In the narrow fabric industry, zipper machines are specialized equipment used to manufacture zippers, which are fastening devices commonly found in clothing, bags, and other textile products. These machines are designed to handle various stages of zipper production, from creating the zipper tape to attaching the teeth and final finishing. Here’s an overview of the key components and processes involved.

Key Components and Processes of Zipper

Machines

Zipper Cord Tape Manufacturing

1- Needle Looms: High-speed needle looms

are used to weave the zipper tape from yarns like dyeable polyester roto yarn.

This tape serves as the foundation for the zipper.

2- Suitable Models: Examples include Jiayi (JY) models like JYZ 10/27, JYZ 12/20, and JYW 14/27, each equipped with grooved rollers for single tape production.

Monofilament Coil Making

· * Coiling Machines: These machines create the continuous coil of polyester monofilament, which forms the teeth of the zipper. The coil is stitched onto the zipper tape using specialized needle looms.

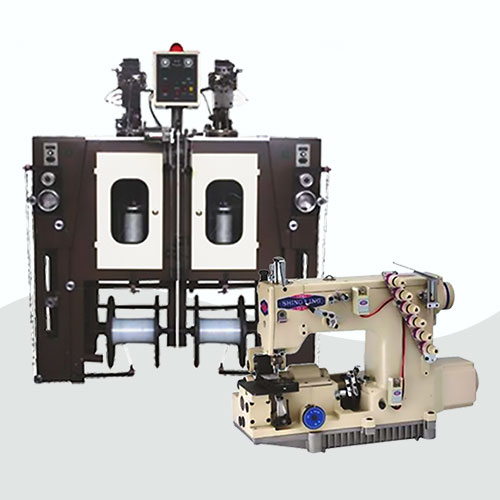

Stitching

* High-speed Sewing Machine : The monofilament coil is stitched onto the zipper tape using high-speed sewing machines. Thes machines ensure precise and durable attachment of the zipper teeth.

* Suitable Models : Sting ling models like SSL860 with clutch, SL 860 with servo motor are commonly used for this process.

Dyeing

* Dyeing Machines: After the zipper cord tape is

manufactured, it is dyed to the desired color. Dyeing machines come in

various capacities, such as 5 kg, 10 kg, 25 kg, 50 kg, and even 500 kg,

allowing for flexibility in production volumes.

* Brand: Wenli is a notable brand providing dyeing machines.

Finishing/Pressing

* Ironing Machines: The dyed zipper is finished

using ironing machines designed specifically for nylon zippers. These machines

improve the appearance and functionality of the zippers and come with options

for oil or steam heating.

* Suitable Models: Wenli models like 8002400, 8002000, and 600*2000 are used for this purpose.

Packing

* Winding Machines: The final step involves

packing the zippers into rolls or specific lengths using winding or

yardage machines. This process ensures the zippers are ready for

distribution and use in various applications.

* Variants: Options include packing in meters or yards, depending on the customer's requirements.

*Brand: Wenli is a common brand for packing machines.

Applications

Zipper machines in the narrow fabric

industry are used to produce zippers for a wide range of applications,

including:

Nylon Long Chain Zipper Machine

Vision

Zippers:

Commonly known as plastic zippers, Vision zippers have individually injected

molded teeth fused directly onto the zipper tape. These zippers are made from

cost-effective materials, making them an economical option. The

high-performance polyacetal resins (Delrin) used in manufacturing Vision

zippers are incredibly strong, durable, and flexible, making them ideal for

children's clothing and outdoor applications.

Manufacturing Process

1.

Zipper Cord Tape Manufacturing

The first step in making

Vision zippers is manufacturing the zipper tape. This tape is produced using

our high-speed needle loom with dyeable polyester roto yarn.

Suitable Models:

- * JYZ 10/27 with grooved roller (Single tape)

- * JYZ 12/20 with grooved roller (Single tape)

- * JYW 14/27 with grooved roller (Single tape)

Brand: Jiayi (JY)

2. Monofilament Coil

Making

The zipper tapes serve

as the fabric sides on which the continuous coil of polyester monofilament is

stitched. This is done using our high-speed needle loom.

Coiling Machine: Specialized machine for creating continuous coils.

3. Stitching

In this process, the monofilament coil is stitched onto the zipper tape using a high-speed zipper sewing machine.

Suitable Models:

1- SL 860 with clutch

2- SL 860 with inverter meter

3- SL 860 DS with servo motor

4. Dyeing

Brand: Shing Ling

After the zipper cord tape is made, it is dyed to the desired color using a dyeing machine.

Suitable Variants:

- * 12 cups sample

- * 5 kg, 10 kg, 25 kg

- * 50 kg, 500kg

Brand: Wenli

5.

Finishing/Pressing

Post-dyeing,

the next step is ironing, where the dyed zipper is finished using a specialized

nylon zipper ironing machine. This machine is designed for high productivity

and offers two heating options: oil or steam. It features three drums: two

large hot drums and one small cold drum.

Suitable Models:

- 800*2400

- 800*2000

- 600*2000

6. Packing

* Packing in meters

* Packing in yards

Brand: Wenli

The

final process in CFC zipper manufacturing is packing or winding the zippers

into rolls using a winding or yardage machine.

Variants:

Brand: Wenli

Vislon

zippers, commonly known as plastic zippers, are made by individually injecting

molded teeth directly onto the zipper tape. This process uses inexpensive

materials, making Vislon zippers a cost-effective option. The high-performance

polyacetal resins (Delrin) used in their manufacture provide exceptional

strength, durability, and flexibility. These zippers are ideal for children's

clothing, outdoor gear, and more.

Manufacturing Process of Vislon/Plastic

Zippers

1. Zipper Cord Tape Manufacturing

The first step in making Vislon zippers is

manufacturing the zipper tape. This tape is produced using high-speed needle

looms with dyeable polyester roto yarn.

Suitable Models:

* JYZ 10/27 with grooved roller (Single tape)

* JYZ 12/20 with grooved roller (Single tape)

* JYW 14/27 with grooved roller (Single tape)

Brand: Jiayi (JY)

2. Dyeing.

After manufacturing the zipper cord tape, the next step is dyeing it to the desired color. This process is done using dyeing machines available in various capacities

Suitable Variants:

* 12 cups

* 5 kg, 10 kg, 25 kg

* 50 kg and 500kg

Brand: Wenli

3. Finishing/Pressing

Following

dyeing, the zipper cord tape undergoes finishing through ironing. This step is

performed using specialized finishing/pressing machines designed for high

productivity.

Ironing Machine Options:

- * Drum-type zipper tape ironing machine

- * Box-type ironing machine

4. Injection Molding

Plastic

zipper injection molding machines are used to produce the molded teeth. These

machines are efficient, producing up to 70 rolls of 100 yards per single color

while consuming only 8 kW of power. They are known for high quality, ease of

operation, low maintenance, and energy efficiency.

Suitable Variants:

- * Plastic zipper injection molding (normal

motor)

- * Plastic zipper injection molding (servo motor)

Brand: Longhri

5. Packing

The

final step in manufacturing Vislon zippers is packing or winding them into

rolls. This is done using winding or yardage machines.

Packing Variants:

- * Packing in meters

- * Packing in yards

Brand: Wenli

By

following these processes, Vislon zipper machines ensure the production of

high-quality, durable, and flexible zippers suitable for various applications.

Metal

zippers consist of two rows of metal teeth molded onto either side of the

zipper tape at regular intervals. Depending on the material used and the

manufacturing process, metal zippers can be categorized into two main groups:

1. Teeth Formed from Metal Wire: Made from brass, aluminum, nickel, or brass, these teeth are either flat or profiled.

2. Teeth Die-Cast Directly onto the Tape: Made

from zinc metal. These zippers are further categorized based on their finishes, such as brass, antique brass, gunmetal, and silver, achieved through chemical treatment of the zipper chain. Metal zippers are suitable for application involving heavy or thick materials such as leather jackets, shoes, heavy, shoes, heavy, shoes, luggage and bags.

Types of Metal Zipper Teeth

* Normal Teeth

* Y-Type Teeth

1. Needle Loom - Zipper

Tape Making

Zipper

tapes are the narrow fabric on which the metal teeth are fixed. The polyester

zipper tape is manufactured with a side cord using high-speed needle looms with

grooved rollers.

Suitable Models:

* JYZ 10/27

* JYZ 12/20

* JYW 14/27

2. Zipper Teeth Fixing

Configuration: Single tape with grooved

roller

Normal Teeth Zipper: In this process, teeth process, teeth are formed from flat wire using an auto metal zipper chain-making machine. One side of the zipper tape and flat metal wire serve as raw materials to produce single-side zipper tape stamped with brass teeth.

Specification:

1- Model: WL-117 J

2- Voltage: 415 V

3- Power: 0.75 KW

4- Production: 258 M/H

5- Dimensions: 800 x 600 x 1400 mm

6- Operating Space: 4 m

7- Noise: 70 dB

8- Net Weight: 250 kg

9- Package Size: 850 x 780 x 1600 mm

3. Dyeing

After

manufacturing the zipper cord tape, it is dyed to the desired color using

dyeing machines.

Suitable Variants:

* 12 cups

* 5 kg, 10 kg, 25 kg

* 50 kg, 500 kg

Brand: Wenli

4. Finishing and Pressing

After

dyeing, the zipper cord tape undergoes finishing through ironing using

finishing/pressing machines.

Ironing Machine Options:

* Drum-type zipper tape ironing machine

* Box - type ironing machine

5. Y-Type Teeth Zipper

Y-type teeth are formed from y-section wire using an auto metal y-type zipper chain-forming machine. This machine is available in two configurations:

* Single head

* Double head with automatic teeth joining device

6. Polishing

* 4 brush

* 12 brush

* 24 brush

7. Ironing and Waxing

The Y-type zipper produced in the previous step has rough edges. These rough edges are smoothed out using an auto metal chain polishing machine with suitable metal brushes.

Suitable Variants:

The final step involves ironing and waxing the metal teeth using an automatic metal chain ironing and waxing machine.

8. Winding

The

finished zippers are packed or wound into rolls using winding machines.

Variants:

* Packing in meters

* Packing in yards

Brand: Wenli

By

following these processes, metal zipper machines ensure the production of

high-quality, durable, and aesthetically pleasing zippers suitable for a

variety of applications.

Explore Our All Products

Contact Information

how we can help elevate your production processes.

Texzium International Private Limited

Our Team Is Here To Help